GALVALUME: PROTECTING AND PRESERVING STEEL

Posted on November 22, 2019 by Heritage

Paint systems certainly play a role in protecting steel building panels from damaging elements. However, the coating between those paint systems and the steel substrate of the panels is arguably more important. In this post, we’ll review Galvalume—the industry-leading steel coating—and offer evidence of its vital role in preserving the aesthetics and structural integrity of steel panels.

What is Galvalume®?

Galvalume is a thin, corrosion-resistant coating applied to raw steel using a continuous hot-dip process. The combination of aluminum, zinc and silicon found in Galvalume-coated steel panels delivers unmatched protective properties. This is especially the case against the ill-effects of water and other oxidation-promoting substances. These include:

- Corrosion resistance

- Heat reflectivity

- High temperature oxidation resistance

- Formability and protection of cut edges

- Better adherence of primer and paint

Why Galvalume® over Galvanized?

Both Galvalume and Galvanized coatings sacrifice themselves to protect the base metal they cover. However, the way in which they do this impacts their structural integrity and lifespan.

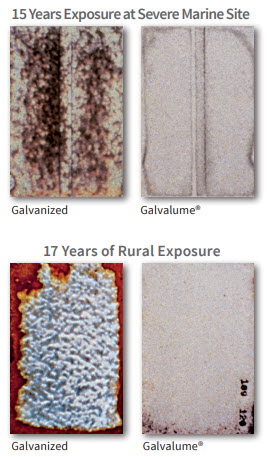

Galvanized sheets feature 100% zinc coatings on both sides—with no aluminum included. This leaves them vulnerable to a faster rate of oxidation and doesn’t offer the level of scratch-resistance and barrier protection for cut edges as found with Galvalume. In fact, although Galvalume can initially show signs of corrosion faster that Galvanized, exposure comparison tests reveal that Galvalume is up to nine times better in fighting corrosion.

Why do Galvalume Panels Show Signs of Corrosion Before Galvanized Panels?

Although corrosion may become visible faster, the sacrificial nature of Galvalume keeps the corrosion from spreading. Galvanized panels—on the other hand—will not show corrosion as quickly. However, once there is corrosion—the coating can’t keep it from spreading. This means the panel will continue to corrode until its structural integrity is lost.

Lifespan, Paint Coatings and Warranty Protection

According to a study released by the Metal Construction and Zinc Aluminum Coaters associations, the longevity of a low-slope unpainted Galvalume standing-seam roof is 60 years. To help ensure this longevity, it’s important to understand that the integrity of Galvalume panels can be compromised by contact with dissimilar metals like copper, lead and iron. Additionally, standing water, harsh chemicals, graphite, masonry products and treated lumber should also not come in contact with Galvalume panels.

Additionally, Galvalume panels coated with Signature® 200 and Signature® 300 silicone-polyester paint systems offer additional resistance to chemical corrosion and ultraviolet radiation. For this reason, they carry a 25-year limited paint finish warranty that guarantees against chalking, fading, peeling and cracking. This makes them an aesthetically-pleasing long-term investment for steel buildings of all kinds.

To learn more about the Galvalume-coated steel building materials offered by Heritage Building Systems, reach out to your local Heritage Building Systems representative or request a quote.